Hydrogen Vehicles in India

India is working on many fronts with respect to sustainability (to achieve net zero by 2070) and present govt has speed up the work in some projects such as the enhancement of solar energy by installing Solar panels to generate electricity in large amounts (in MWatt), blending of ethanol in petrol (E10 & E20 petrol), encouraging manufacturing & using of electric vehicles, by making policies (FAME-I & II) which will make people to adopt small capacity rooftop solar system on residential buildings, Govt offices etc.

Apart from this, Govt is working on Hydrogen which can be used for vehicles as a fuel. Union Minister said recently at a function that India will roll out its first Hydrogen-powered train on the next Independence Day. This project will have design, development & manufacturing indigenously. First, let’s understand about hydrogen fuel & how it works.

What is Hydrogen –

Hydrogen (H2) is an element that is in gas form at normal temperature & pressure, but it becomes liquid on very low temperatures (-253 deg, C). It is available on earth in compound form with other substance such as in liquid (petroleum), gas (natural gas) or solids (coal) as these substances are made up with hydrocarbons & available in large quantities. Hydrogen can be produced from different sources like nuclear power, biomass, natural gas etc.

Hydrogen is a very good source of energy carrier & has the highest energy content per unit weight than any other fuel (almost 3 times more than gasoline), also it has lowest energy content than gasoline (almost four times less than gasoline). It has one more advantage that it can be stored, and transported easily and can produce electricity. (Note- gasoline means petroleum).

Hydrogen can be produced commercially through different processes but thermal processing & electrolytic are very common. In thermal processing, steam reacts with hydrocarbon fuels which in turn produce hydrogen.

Difference between Hydrogen Fuel Cell Vehicle & Electric Vehicle –

Hydrogen vehicles in India are almost similar to electric vehicles wherein both vehicles use electricity to run the motor, but basic difference is that hydrogen fuel cell produce electricity within the vehicle while external electricity source is required for electric vehicle. Like any other fuel tank, hydrogen can also be stored in a pressurized tank of the vehicle. The H2 is used by fuel cell (an important part of the vehicle) to produce electricity to power the motor. H2 vehicle also has an inbuilt battery system which can store electricity produced by H2. It doesn’t produces any fumes / smokes like an electric vehicle. That is why it is considered as a clean/green fuel.

What is Hydrogen Fuel Cell–

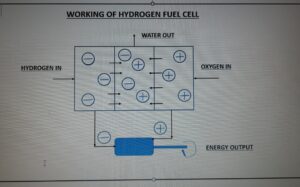

H2 fuel cell is an important part that utilizes hydrogen gas into electric power (or works as a power generator) that makes possible the idea of H2 vehicle. In 1950s, NASA (national Aeronautics & Space Administration) used H2 as a rocket fuel with the help of fuel cell technology. The working of Hydrogen can be understood from the diagram given below. This cell works like a battery when hydrogen & oxygen atoms come in contact with each other. This process produces power, water & some heat.

Govt’s plan on hydrogen fuel –

Niti Ayog (National Institution for Transforming India) which is “Think Tank” of Govt of India provides directional & policy inputs. It also provides relevant technical information to center & state while designing strategic & long-term policies & programs for Indian Govt.

Niti Ayog has framed some policy with respect to usage of hydrogen in Indian context. Niti Ayog has collaboration with RMI which is nonprofit organization that provides solution for clean energy through market driven solutions. Transport ministry has started working on to use hydrogen as a fuel for vehicle purpose. Recently we have seen that Mr Nitin Gadkari reached Parliament with Hydrogen car Toyota Mirai. Hydrogen car is also known as Fuel Cell Electric Vehicles (FCEV). Govt is also working on Hydrogen Train which is to be launched on next Independence Day.

Conclusion – We can hope that the way present govt is working on all fronts of sustainability, we will reach to net zero target before 2070.