LED

LED; LED Lights; LED Full Form; Different type of LED lights; Application of LED lights;

Definition –

A light-emitting diode (LED) is a two-lead semiconductor light source. It is a p–n junction diode, which emits light when activated. When a suitable voltage is applied to the leads, electrons are able to recombine with electron holes within the device, releasing energy in the form of photons.

Full form of LED is Light Emitting Diode. Its a solid state device and doesn’t require heating of a filament to create light. Rather, electricity is passed through a semiconductor material that is excited and generates light. LEDs are not bulbs or lamps in the true sense. To make it usable as bulb, LED chips are placed on a circuit board or other material that allows electricity to pass through at a specific voltage and current and with components required to operate them at specific voltages.

Enclosures are plastic, aluminum or metal composites with various types of lens/covers.

A group of LEDs set in a square, rectangular or linear pattern and formatted to be operated at a specific voltage.

Application of LEDs / Purpose of LEDs –

These days LEDs are being used for various purposes in our daily life. Some examples are given below –

- Lighting

- LED TV

- Mobile phones

- Digital devices where screen is required or for indicating purpose such as

- Computer,

- Laptop,

- Calculators,

- Projectors,

- Infotainment system of car etc.

5. Torch

6. Traffic signal

7. Building façade light

8. Backlit watches

9. Car/vehicle head lights

10. LED lamp etc.

CONSTRUCTION OF LED FIXTURES –

LED light consists of small-small LED chips which are connected in series & parallel combinations. Each LED chip is designed for 3V, 3.5V DC and 350mA, …900mA current. These LED chips are connected in series & parallel on a PCB (Printed Circuit Board) according to the design of light. These lights are designed for either constant voltage or constant current. Accordingly each PCB is required a particular voltage which may vary from 12V to 50V. This is provided by a control circuit called driver. A driver receives 230VAC & gives DC voltage to PCB. As driver is an electronic circuit, the functions of driver are –

- To reduce input single phase ac supply, 230VAC to 12V – 50V, on which LED operates as per design,

- It is designed to control the power factor of the light more than 0.9,

- It is designed to control the harmonics which are generated during operation of lights,

- It is designed to protect light from surge voltage. For example – indoor lights are designed for 2KV or 3KV surge protection & outdoor lights are designed for 5KV -10KV surge voltage protection.

(Note: – When LED glows, it generates heat. This heat plays an important role in the performance of driver. Hence, proper heat dissipation is very important factor for long life of the drivers. That is why in LED lights, fire resistant PCB (Printed Circuit Board) is used for the driver.)

Heat dissipation is done by using metallic base for LED lights. In some lights this driver is installed inside the case of the light & in some cases outside. Outside installed driver is better for long life of the driver.

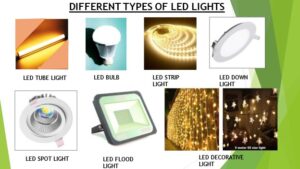

Different types of LED lights/fixtures are available in market –

Various types of LED lights are available in market for domestic & commercial purpose. Some examples are given below –

- LED Tube light

- LED strip light

- LED Bulb

- LED down light

- LED spot light

- LED flood light

- LED decorative light

ADVATAGES OF LED LIGHTS –

- They don’t generate heat.

- LED lights are energy efficient & its estimated energy efficiency is 80% – 90% when compared with traditional Incandescent bulb.

- No toxic chemicals are used in LEDs as compared to fluorescent bulb that contains mercury.

- As no UV emission is done by LED, they are useful where UV sensitive material /objects like museum art galleries, archeological sites etc.

- LED light scan be designed in any shape & lighting effect because individual LEDs can be controlled.

- LEDs are suitable to operate in all weather conditions without any problem. While in fluorescent bulb, low temperature affects the operation of bulb.

- Low voltage supply is required to operate LED which is suitable for outdoor activity and very useful for lighting in rural area.

- LED lights are suitable for outdoor lighting system as they are resistant to shock, vibration, external impacts. Also These lights can be easily focused at one location.

DISADVANTAGES OF LED LIGHTS–

- Expensive – LED lights are very expensive as compared to fluorescent or incandescent light.

- Color change – LEDs can change its color due to age & temperature.

- Brightness – LEDs emit lower output levels over a very long period of time and become less bright.

- Expertise – LEDs must be supplied with correct voltage or current & this required highly engineering expertise.

SELECTION OF LED LIGHTS–

Following points should be considered while selecting an LED light –

- Lumen /watt – These days LED lights are designed between 80 -120 Lumens/Watt. It means intensity of light is directly proportional to the lumen, higher the lumen means higher the light intensity. Therefore, we should select higher lumen/watt light. Higher lumen per watt light saves energy also.

Ex. – Suppose 1000 lumens are required for an area. First let us select 80Lumens/watt. So for 1000Lumes – 12.5W (1000/80= 12.5W)LED light is required while for 110 lumens/watt – 9W LED light is required for same 1000lumes light.

- Burning Hours – We should ask for maximum burning hours of the light. Number of burning hours depends on the operating hours of the light. For 24X7 operations, number of operating hours less as compared to 12X7 operating hours. These days, internal & external light fixtures are available for 50000 burning hours while LED lamps are available for 25000 burning hours.

- Built-in protection – We should ensure built-in protection provided in the light fixtures like power factor, surge protection, THD (Total Harmonics Distortion),

- Make of Driver & LED Chip – We should ensure that make of driver & chip should be of reputed make.

- Warranty – We should ask for the warranty of the light fixture.

- Ask for LM 79 & 80 reports of LED lights.

LM 79 & 80 REPORTS –

LM 79 Report– This report ensures the overall performance of LED fixtures which includes light output (lux level), wattage (electrical power), lumens per watt, drive current (mA), color temperature, efficiency & intensity distribution.

- LM 80 Report– This report ensures the performance of LED in terms of lumen maintenance which measures the lumen depreciation of LED at various temperature through testing hours between minimum 6000 hrs. to 10000 hrs.

FAQs

Q1- Is LED light available in different colors?

LED lights have added advantage as compared to other lights as they are available in different colors for example white, red, blue, green etc. but there some specific colors which are used in offices, educational centers & residential purpose, these colors are –

- Warm- 2700K

- Warm white – 3000K

- Cool light- 4000K

- Day light – 5000K

Where K is Kelvins which is used to measure the color in lighting. It is defined as “the SI base unit of thermodynamic temperature, equal in magnitude to the degree Celsius.” In other words, we can say that the lower the Kelvin rating (K) the warmer is the light. While all other colors are mostly used for decorative lights, in events etc.

Q2- Why does LED light glow when it is off?

Ans – This problem has been noticed many times by the user of LED lights. This happens because of poor quality of LED driver. A driver is a controller of LED light that receives 230V ac supply & provide required DC voltage to controller PCB. LED light driver performs following functions –

- To reduce input single phase ac supply, 230VAC to 12V – 50V, on which LED operates as per design,

- To control the power factor of the light more than 0.9,

- To control the harmonics which are generated during operation of lights,

- To protect light from surge voltage.

(For example – indoor lights are designed for 2KV or 3KV surge protection & outdoor lights are designed for 5KV -10KV surge voltage protection.)

Therefore the quality of driver of LED lights plays very important in the performance of light.

Q3 – Does LED light harmful to our eyes?

Ans – All lights including LED produce blue light & direct exposure of our eyes to blue light is harmful. Let’s understand like this that light is an agent that stimulates sight & makes thing visible. There are two types of sources of light -Natural such as Sun & Man-made such as LED, CFL, Incandescent bulbs & any other digital screens. (Note- These days almost all digital screens use LED lights in different forms).

All above light sources produce visible & invisible light rays, the percentage of these light rays vary according to its source (percentage is more in natural light source as compared to manmade light). When a light passes through a PRIZM, it is divided into 7 different colors which is called VIBGYOR. Where V- Violet, I- Indigo, B- Blue, G- Green, Y- Yellow, O- Orange, R- Red.

Each light color produces some amount of energy which is given below –

R O Y G colors produce energy ranging between web-length of 500- 700 mn and B I V colors range between web-length of 380- 500 mn. The low range lights (B I V) have very high energy level as compared to high range colors (R O Y G). The high intensity/energy level colors B I V is also called blue light & are harmful to our eyes if we look at light for a long period because our eyes are not good at blocking blue light.

The manmade light sources emit light a fraction as compared to Sun, but the amount of time people spend using these devices, & the proximity of these screens/lights to the user’s face are the main concern.

Effect of blue light – It causes strain & vision problem in our eyes.

How to protect our eyes from blue light –

A – From Sun (natural sun light)- We all know the intensity of sun light & we can’t dare to look at Sun directly. If we will try to do so, the sun light will damage our eyes very badly. So, pls don’t look at sun with our naked eye at all.

B- From man devices – There are three items which are commonly used in our daily life for a long period which may slowly damage our eyes, these are – Mobile phone, Computer & LED lights.

- Mobile phone – there are various ways by which eyes can be protected by following actions –

- Brightness – use mobile phone on low brightness. These days mobiles are coming with auto adjustable brightness.

- Blue light filter – new mobiles are coming with Blue light On/Off feature.

- Tempered glass – It reduces the effect of blue light & also provides protection to mobile screen from scratch,

- Computer – Filters are available for tablets, and computer screens and prevent significant amounts of blue light emitted from these devices.

- LED lights – As it is an energy efficient lighting source which is the need of hour. Therefore, the best way to protect our eyes from it – to avoid staring at LED light for a long time unnecessarily. However the percentage of damage to our eyes due to LED is very less as compared to other two devices like mobile phone & computer because the exposure of LED light to our eyes is not direct until unless we don’t stare at it & get exposure.