FLUORESCENT TUBE

Fluorescent Tube-

Principal –

Fluorescent lamps work by ionizing mercury vapor in a glass tube. This causes electrons in the gas to emit photons at UV frequencies. The UV light is converted into standard visible light using a phosphor coating on the inside of the tube.

Working –

A tube light/rod if made up of 4 ft. long glass tube whose inner side is coated with phosphor & it is filled with mercury vapor. It has two metal electrodes/filaments at both ends. To complete its operation two more items are required – 1) Choke & 2)Starter.

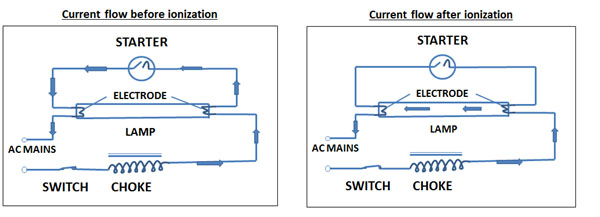

When we switch on light, the current passes through the choke then one of electrodes & reaches up to starter. Initially no current flows through the starter as starter’s contacts are open,these contacts are surrounded by a gas. This gas starts heating up and makes the gas ionized & current flows through it. When current starts flowing through the starter, gas starts cooling down & which stops the current to flow as it de-ionize of gas in the starter. This process is repeated. During this process of ionization/deionization of gas in the starter, a high voltage is generated by the choke which causes ionization of inert gas in the tube.

In few attempts, the gas inside tube gets fully ionized (an arc is set up) between two electrodes & current starts flowing from one electrode to another electrode & tube light stats glowing (or light is emitted). Once the gas is ionized the high voltage is reduced to a great extent for normal operation of tube light no current flows through starter.

The ionization of mercury gas causes electrons in the gas to emit photons at Ultra Violet light (or frequencies or radiation). The UV light hits the phosphor coating inside it & coating glows to produce visible light.

FUNCTION OF CHOKE –

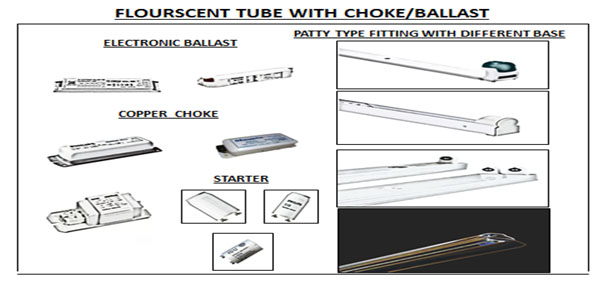

There are two types of chokes used in fluorescent – electromagnetic & electronic.

Choke (or Magnetic choke/ballast) –

The function of choke is to produce very high voltage between the two electrodes (across two ends of tube). Once the gas is ionized, a path is created (an arc is set up) between two electrodes & current starts flowing through it, then there will be no current through the starter. The starter stops functioning & choke provides low voltage.

Choke limits the current also when arc takes place between two electrodes in order to avoid lamp to burn out or cause the power supply to fail.

Choke is able to produce high voltage with help of starter. The starter switches on & off the current (passing through choke) very frequently (causes flickering of light) which produces very high voltage across the choke & hence between the ends of tube.

The starter will continue to function till the time the gas is ionized inside the tube.

Since the starts stops functioning, no more high voltage is across the choke. And the voltage across the choke (and between the filaments) is very much reduced.

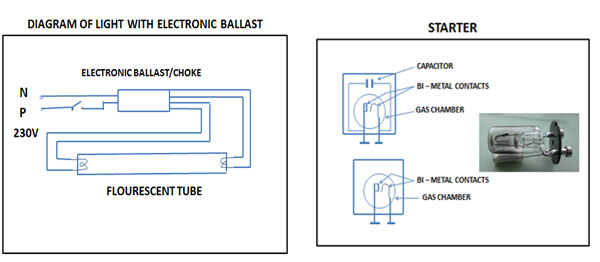

Electronic Ballast –

Electronic ballast performs the function of both Choke & Starter. When electronic choke is used with light then starter is not required. Electronic ballast converts AC to DC and then back to AC at a higher frequency to operate the lamp. There are two primary functions of the electronic ballast:

- To provide the initial high voltage required to ionize the gas, thereby setting up an arc between the two electrodes.

- To limit the current through the tube once it has started up. If the current is not controlled it may result in voltage spike thereby damaging the lamp.

The other functions of electronic ballast include ignition, warm-up, constant power control, power factor correction, and protection against all lamp and ballast fault conditions.Electronic ballast operates at 20 KHz-80KHz unlike the magnetic ballast which operates at 50 -60 Hz. At high frequency the lamp requires less input power, thereby increasing the efficiency.Electronic ballast is used to operate Fluorescent Lamp, neon lamp or High Intensity Discharge (HID) lamp.

Wiring diagram of fluorescent lamp with electronic ballast –

FUNCTION OF STARTER –

The starter consists of a small bulb containing a gas (usually argon) and a bi-metal contact (normally not touching with each other). When power is applied to the fixture and current is unable to flow through florescent lamp then an arc is produced (through argon gas) in the starter & current flows in it and gas in the starter heats up & one of the metal contact starts bending. When the gas is sufficiently heated up, the bi metal moves out of the position & creates a direct path for the current in the starter. Now the maximum amount of current flows through the filaments /electrodes of the fluorescent lamp which heats up the gas in the lamp.

Meanwhile, in this situation, no arcing takes place in the starter & starter starts cooling &bi-metal contact will begin bending back to its original position. This process repeats till the mercury vapour is ionized in the lamp& current starts flowing through it. Once fluorescent bulb successfully starts, the starter bulb continues to cool and eventually the bi-metal contact returns to its “rest” position. The starter is deliberately designed to have a higher break-down voltage than the much-longer fluorescent lamp. The starter also has the resistance of the two filaments in the fluorescent lamp as part its electrical circuit.

Some starters also contain a capacitor (also known as a condenser) that can reduce electrical noise and assist in the starting process.

TYPE OF FLUORESCENT LAMPS –

Fluorescent lamps are available in different shapes & sizes – T5, T8 & T12. Where T stands for tubular shape & number indicates the diameter of tube. For ex. –

a) T5 where 5 means 5/8”.

b) T12 tube lights were the first tube light which had diameter of 38mm (=12/8”).

c) T8 lights have diameter (25mm= 8/8”) less than T12 while T5 (16mm) tubes have less diameter than T8.

(Note- These days T12 are no longer being manufactured due to inefficiency.) Following types of lamps are available in market –

- According to length – 4 ft& 2 ft

- According to diameter – T12, T8 & T5,

These are available in following wattage – 36W in 4ft length, 18W in 2ft length etc.

Frequently Asked Questions (FAQs) on Fluorescent Tube/Lamp-

Q1) How to dispose of fluorescent tube?

Ans) Fluorescent tube is a device that contains glass, phosphor coating on glass & filled with mercury vapour. It’s a kind of e-waste so after use, it should be disposed-off carefully.

Therefore, consumers or bulk consumers of electrical and electronic equipment shall ensure that such waste when generated is channelized through collection center or dealer of authorized producer or dismantler or recycler or through the designated take back service provider of the producer to authorized dismantler or recycler.

But, If fluorescent tube is not in use at home, then it should not be mixed with other waste items. Put it in a plastic bag, write e-waste on it & keep it separate from other waste. Handover this packet to the garbage collector of your area. The authorized collector will dispose of this waste as per the local norms.

Q2) How many lumens in 40W fluorescent tube? Or Lumen efficiency of fluorescent?

Ans) let’s say – an average luminous efficiency of fluorescent tube is – 60 lm/w, therefore total lumens of a 40 W fluorescent tube is 40 * 60 = 2400 lm/w.

(Note- For your rough calculation purpose, consider some specific average lumen efficacy for lamps such as Incandescent – 15 lm/w, Halogen-20 lm/w, Fluorescent – 60 lm/w, Metal Halide – 87.5 lm/w, High Pressure Sodium – 117.5 lm/w, Low Pressure Sodium – 150 lm/w, Mercury Vapor – 50 im/w.)

Let’s understand following terms to understand more about it –

Lumens – Lumens represents total light intensity from a single source or it is an output of the lamp/tube/bulb in terms in terms of light intensity. Lumens are directly proportional to the light intensity, more lumens means more intense or brighter the light & vice versa.

Lumens Efficiency/efficacy of light – It is a measure of visible light that is produced by a source. Lumens efficacy is the ratio of luminous lux to watt & its unit in SI is Lumens per watt (lm/w).

Lumen maintenance – It is a gauge to determine the useful light output (or life time) of a lamp after its usage for a specific time or in other words lumen maintenance is the remaining lumens of a lamp after its use for a specific time when compare with initial output. For example- If a lamp of 15W produces 1200 lumens when it was new & after 20000 hrs it produces let’s say 1000 lumens, then this luminaire /lamp has 80% of 25000 Hrs.

Colour Rendition – It is also known as colour rendering. Colour rendition is the effect of light with respect to colour that is observed/seen by humans. These colours are represented by Colour Rendering Index (CRI) ranging from 0 to 100. Higher CRI rating represents better colour rendering ability & vice versa.

(Note– Colour rendering is different from colour temperature. Colour temperature describes colour appearance of the light source when its on while colour rendering describes how well the light renders in colour objects.)

Table 8 Luminous Efficacy, Life, Lumen Maintenance & Colour Rendition of Light Sources (As per NBC -2016)

| S. No | Light Source | Wattage Range (W) | Efficacy (lm/W) | Average Life (h) | Lumen Maintenance | Colour Rendition |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) |

| I | Incandescent lamps | 15 – 200 | 12 to 20 | 500 to 1000 | Fair to good | Very Good |

| Ii | Tungsten Halogen | 300 to 1500 | 20 to 27 | 200 to 2000 | Good to very good | Very Good |

| Iii | Standard Fluorescent Lamps | 20-80 | 55 to 65 | 5000 | Fair to good | Good |

| iv | Compact Fluorescent Lamps (CFL) | 5-40 | 60 to 70 | 7500 | Good | Good to very good |

| v | Slim line Fluorescent | 18-58 | 57 to 67 | 5000 | Fair to good | Good |

| v | High pressure mercury vapour lamps | 60 to 1000 | 50 to 65 | 5000 | Very low to fair | Federate |

| Vi | Blended-light lamps | 160 to 250 | 20 to 30 | 5000 | Low to fair | Federate |

| Vii | High pressure sodium vapour lamps | 50 to 1000 | 90 to 125 | 10000 to 15000 | Fair to good | Low to good |

| vIii | Metal halide lamps | 35 to 2000 | 80 to 95 | 4000 to 10000 | Very low | Very good |

| Ix | Low pressure sodium | 10 to 180 | 100 to 200 | 10000 to 20000 | Good to very good | Poor |

| x | LED | 0.5 to 2.0 | 60 to 100 | 10000 | Very good | Good for white LED |

NOTES

1 The table includes lamps and wattages currently in use in buildings in India.

2 Luminous efficacy varies with the wattage of the lamp.

3 Average life values are from available Indian Standards. Where Indian Standard is not available, values given are only indicative.

4 For exact values, it is advisable to contact manufacturers.

Q3) Why fluorescent tube flickers? Or flickering of tube light is normal?

Ans) No. Flickering of tube light is not normal. If, it is happening then it may be due to either loose connection of wires within tube or by defective choke/ballast, or by defective starter. If tube is defective due to internal fault, then the end of the tube turns dark. So, check all these issues one by one & take corrective action.

Q4) Why a choke of fluorescent tube is called ballast?

Ans) A choke (or an inductor) of a fluorescent tube is also called ballast because it produces very high voltage between the two electrodes (across two ends of tube) which creates a path (an arc is set up) between two electrodes by ionizing the gas & tube starts glowing. (Complete details of choke is given in above “Choke” section.)

Q5) Why are fluorescent tubes called shadow-less lights?

Ans) Normally a fluorescent light is called shadow less light because it emits light from all over the surface of the tube & spreads light in all directions & covers major area of the object. That is why it creates very less shadow or almost no shadow. On the other hand, a bulb which is like a point source of light that creates bigger shadow because it covers less area of the object.

Q6) Why does a fluorescent tube not generate heat?

Ans) First of all Fluorescent tube doesn’t have any filament that is heated up by electrical power & produce light. This happens in incandescent bulbs that is why heat is produced in it. While in fluorescent tubes, electricity is used to make the connectivity through arc between two ends of it, this arc radiates energy that causes electrons in the gas to emit photons at Ultra Violet light. The UV light hits the phosphor coating inside it & coating glows to produce visible light.

In this process some amount of heat (very less as compared to incandescent bulb) is generated.