OIL TYPE TRANSFORMER

What is Oil Type Transformer- Definition of oil type transformer is given below –

Definition –

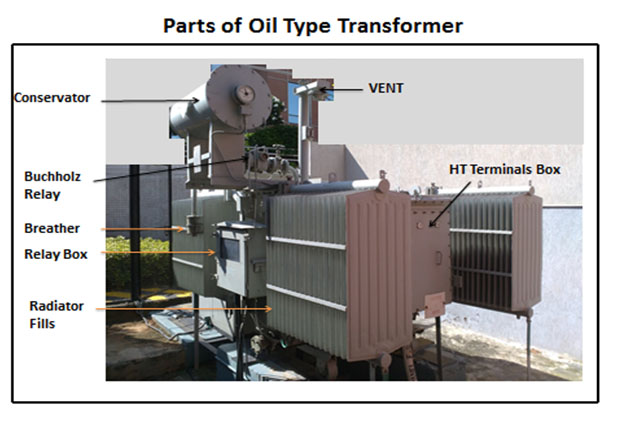

Oil type transformer is a static device. It is called oil type transformer because its core & winding are immersed in the oil. It consists of a tank, core, primary & secondary windings, oil, conservator, breather, silica gel, cooling tubes/fins, Buch howls relay etc. Functions of each part is given below –

-

Tank–

Tank is the main housing of oil type transformer where core & windings are placed. Tank is filled with special oil which is called transformer oil. Core & windings are completely submerged in the oil.

-

Core –

The main function of core is to a) provide flux linkage between primary & secondary windings &b) provide support to the windings. Windings are mounted on the core. Primary & secondary windings are not electrically connected but they are connected magnetically. Core is made up CRGOS (Cold Rolled Grain Oriented Silicon) steel which provides low magnetic path for efficient flux linkage. The max flux density of CRGOS steel is about 1.9 Tesla. Laminated core is used (in place of solid) to reduce the eddy current losses. Laminations are insulated from each other by thin coat of plate varnish.

Various types of core–

Various types of cores are used in transformer like L-type, U-I type & T- type.

-

Windings –

Two windings are mounted on the core, the winding which is connected with supply/source is called primary winding & the other winding which is connected with load is called secondary winding. High or low voltage in secondary winding depends on the number of turns of winding on the core. In step down transformer the number in secondary winding is less as compared to primary. Low voltage winding is mounted on core first & the low voltage winding is covered by high voltage winding.

The function of primary winding is to magnetize the core and the function of secondary winding is to increase or decrease the voltage (as compared to primary voltage).

-

Oil –

Oil which is used in transformer is called transformer oil. Main function of transformer oil is to work as an insulating medium between windings and windings & body, as a coolant & suppress corona and arcing. There are two types of transformer oils – a) Paraffin based transformer oil, b) Naptha based transformer oil.

GenerallyParaffin oil is used in India as it is easily available. Although Naptha based transformer oil forms sludge due to oxidization which is more soluble than paraffin based oil & pour point is also low as compared to paraffin based oil.

The transformer oil should have following properties –

- Electrical properties

- Physical properties,

- Chemical propertie

- Electrical properties – Transformer oil should have following electrical properties – High Dielectric strength& high specific resistance,

- Chemical properties – Transformer oil should have following chemical properties – Low water content (moisture) & less acidic,

- Physical properties – Transformer oil should have following electrical properties –High flash point, low pour point & low viscosity.

DIELECTRIC STRENGTH (OR BDV) OF TRANSFORMER OIL –

Dielectric strength of oil indicates the insulating properties of Transformer oil. High Dielectric strength means high insulating properties & vise- versa. It is also known as break down voltage (or BDV) of transformer oil. 30KV is considered to be safe valueof transformer oil for use.

Testing of BDV – Dielectric strength of transformer oil is deteriorated by moisture contents. Testing of BDV transformer oil is done through a BDV tester. A BDV tester is a small chamber which has two electrodes which are kept 2.5mm apart. Sample oil is filled in the chamber whose BDV is to be checked. Now voltageis applied across the electrodes & voltage is gradually increased at 2KV/s. When oil withstands voltage 30KV or more it means oil is healthy otherwise oil needs some treatment in order to reduce moisture content from oil. This process is repeated 3-4 times from same sample. To reduce moisture from oil, dehydration of oil is done.

Dehydration of oil is a process where unhealthy oil passes through a hot chamber which absorbs the moisture content which causes BDV increases. Once value increases to more than 30KV, oil can be used in the transformer.

IMPORTANT POINTS RELATED WITH TRANSFORMER OIL –

Effect of water in transformer oil –

Water content (or moisture)is not good for the transformer oil. Moisture reduces the insulating property of oil which reduces the BDV of the oil. Water content also affects the paper insulation of core & windings. As per IS, water content is allowed up to 50ppm. More than 50ppm water content is harmful to oil.

Effect of oxidation (or acidity) in transformer oil –

When transformer oil is oxidized, acids are formed. This acid is harmful to the oil as it increases the solubility of water. So acidity & water contents both decompose the oil & hence oil starts losing its properties. Acid causes rusting of iron & increases the rate of oxidization. Acidity is expresses in mg which is also called neutralization number. This neutralize number is used to reduce the acid effect in the oil.

Flash point of transformer oil–

Transformer oil must have high flash point which is generally more than 140deg C. High flash point is very crucial as it is the temperature at which oil starts burning.

Pour point of transformer oil –

Pour point of transformer oil is also an important factor, if temperature of oil falls below the pour point, oil becomes thick & stops convection flowing which obstruct cooling in transformer. Thickness of the oil depends on the wax content. Paraffin oil has higher pour point than Naphtha.

Viscosity of transformer oil –

Transformer oil must have low viscosity, it means low viscosity offers low resistance to the flow of oil which is helpful for the cooling in the transformer. So, transformer oil’s viscosity should not be varied with temperature.

-

CONSERVATOR –

Conservator is a cylindrical shaped container which is installed over the tank. It is also known as expansion tank. Conservator & tank is connected with each other through a pipe which is filled with transformer oil. The main function of conservator is to keep the transformer tank full despite expansion or contraction of the oil with changes in the temperature. It also reduces the rate of oxidation of the oil because 1) less oil surface is exposed to the air, 2) reduced temperature of the oil exposed to the air. Oil volume increases with high temperature & decreases on cooling. Temperature variation depends on load & ambient temperature. It also acts a reservoir for the oil. Conservator should be half filled only. It is usually installed on low voltage side of the transformer tank.

-

BREATHER –

Oil variation in conservator is possible when air is allowed to enter & exit the conservator. Direct entry & exit of air is not recommended as air may have water contents in it which is harmful to the transformer oil. So in order to avoid such situation silica gel is used to arrest water content from air. Silica gel is placed in a cylindrical box at the starting point from where air enters/exits. Silica gel box is connected with the conservator through a pipe. Normally the colour of silica gel is blue but when it absorbs air its colour changes to pink. Pink colour silica gel should be replaced by blue colour again because pink colour silica gel gets saturated & doesn’t absorb water contents.

-

RADIATOR –

Due to losses in the transformer, heat is produced in the windings& core. This heat increases the temperature of oil. So cooling of oil is must for a transformer. Tank alone is not sufficient to control the temperature of oil, therefore radiator plays an important role as it increases the surface area of oil which accelerates the cooling rate. Cooling in radiator happens due to convection in the oil.

-

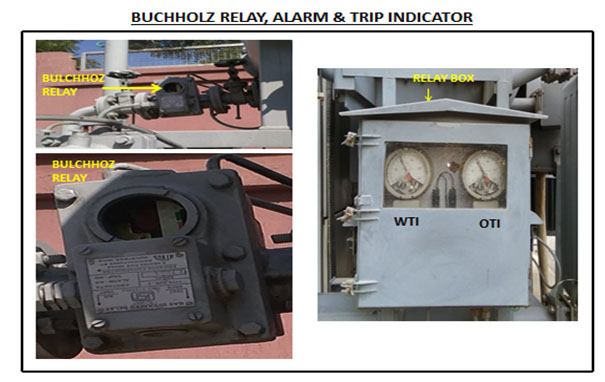

BUCHHOLZ RELAY –

Buchholz relay is used to protect transformer from faults which occurs inside it.It’s a gas operated relay which operates when gases like different hydrogen gases, CO2 & CO etc which may produce due to insulation failure of windings, core heating, break down of transformer etc.These are the faults which may occur in the transformer. If these faults are not detected then these faults may damage the transformer.

Buchholz relay consists of two sets of float balls. One ball is fixed on upper portion of the relay which is used for alarm purpose & second is fixed in lower portion which is used for trip purpose. Both float balls are attached with a separate mercury switch. Mercury switch is a small container which has two contacts & container is partially filled with mercury. In normal case both contacts are separated from each other as mercury is not touching both contacts. Relay is filled with oil (only some top portion is not filled) but under small fault condition,gases are produced in the oil which goes in the upper portion of the relay when these gases are trapped in the upper portion which causes the oil level goes down. When float goes down, mercury in the mercury changes its position,closes both contacts& alarm circuit is energized.

But in case of major fault like short circuit, fault produces surge in the oil which causes float valve at lower portion moves & mercury switch closes its contacts & trip circuit energizes.

(Note– The design of buchholz relay depends the different manufactures, here diagram is given of one of manufacturers).

PROTETION OF TRANSFORMER FROM FAULTS –

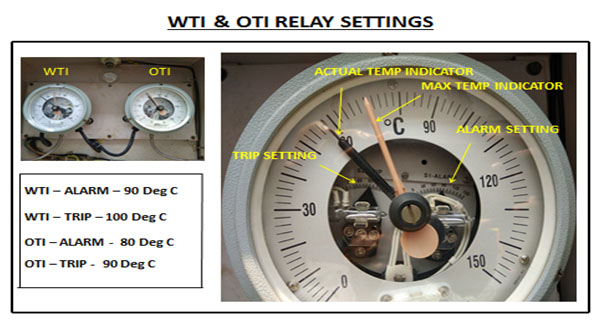

Protection of transformer from various faults is done with WTI & OTI relay which are mounted on the transformer.

WTI (Winding Temperature Indicator) – WTI is a protection relay which protects winding from damage due to high temperature. This relay gives an Alarm indicationwhen the temperature of winding goes beyond a certain temperature. It also gives Trip command to the breaker when temperature increases further and cross a certain value.

OTI (Oil Temperature Indicator) – OTI is also a protection relay which protects transformer from burning oil due to high temperature. This relay gives an Alarm indicationwhen the temperature of oil goes crosses a certain temperature. It also gives Trip command to the breaker when temperature increases further and cross a certain value.

Settings of WTI & OTI Relays –Standard relay setting of a transformer is given in the diagram given below.

(Note- The setting of Alarm& Trip temperature may vary withdifferent manufacturers. So, check WTI & OTI limits accordingly.)

9)VENT –

It is also known as explosion vent or rupture vent. The function of vent is to protect the transformer from excessive internal pressure in the tank. It’s a safety device. An explosion vent is a pipe which has thin aluminum diaphragm at both ends. These diaphragms are protected from mechanical damage with wire mesh at both ends. Internal pressure of oil or gases may build up with high temperature of transformer oil.

Tap changing in Oil type transformer–

Tap changer in transformer is required for voltage regulation. Voltage regulation is nothing but to get desired out output voltage irrespective of the variation of input voltage.

There are two types of tap changers are there – a) OLTC (On Load Tap Changer) and b) NLTC (No Load Tap Changer).

- OLTC (On Load Tap Changer) – In OLTC type transformer, tap changing is done when transformer is running on load & no need to switch off transformer. Tapping arrangement is done in a separate cylindrical tank which is attached with the main tank. Inside the tap changing tank, tap selectors are arranged in circular shape which is filled with oil.

- NLTC (No Load/Off Load Tap Changer) – In NLTC oil transformer, tap changing is allowed when transformer is off & fully discharged

(Note – NBC 16 (National Building Code of India 16) provides complete details of electrical system which are required to follow when a building is constructed. Different sections cover different requirement of electrical system.

Guidelines related with oil type transformers are given in the link below –)