FUSES

What is electrical fuse? – Definition of electrical fuse is given below –

Definition –A fuse is a piece of metal which is inserted in the circuit & melts when current passes through it exceeds its rated limit.

It means Fuse is also used to interrupts the circuit automatically. It is the cheapest form of protection against the excessive current. It is suitable for low to moderate voltage applications. It is used for protection from over load & short circuit currents.

Material for fuse element –

It is made of material having low melting point, high conductivity & least deterioration due to oxidation. So, Silver, copper, tin, zinc, silveretc are the most suitable material used for fuses.For small currents upto 10A, tin of an alloy of lead and tin is used for fuse element while for lager currents, copper or silver is used.

Working principle of electrical fuse–

Under normal condition, fuse carries normal current without overheating. When short circuit/ overload occurs, the current passing through the fuse increases beyond the fuse’s rated vale. Increased current increases the temperature of fuse wire & fuse element melts, disconnecting the circuit protected by it.

Fuse melting (or blow out) time –

The time required to blow out is fuse depends on value of fault current, the greater the current, the smaller the time taken by the fuse to blow out. Or in other words we can say that a fuse has inverse time current characteristics.

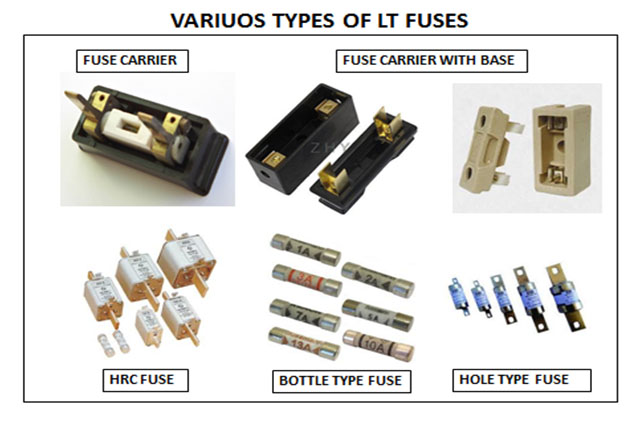

Types of Electrical Fuses –

There are two types of fuses – a) Low voltage fuses & 2) High voltage fuses.

-

LOW VOLATGE FUSES–

These are of two types – i) semi enclosed re-wire able type & ii) HRC (High Rupturing Capacity) cartridge type.

- Semi enclosed re-wire able type fuse – It is also known as kit-Kat type fuse & is used for low vales fault currents. It consists of a base & a fuse carrier. Base is made up of porcelain material. Incoming & outgoing wires are connected with the base ends.

Fuse carrier is also made up of porcelain material & it holds the fuse element. Fuse carrier can be fixed or detached with base when required.

When fault occurs, fuse is blown out & circuit is interrupted. The blown fuse can be replaced by new one after detaching the fuse carrier from the base.

- HRC cartridge type fuse – It consists of a heat resisting ceramic body having metal end caps. A silver current carrying element is welded between end caps. There is a space surrounding the element & within the body, filling powder is packed. This filing material may be chalk, Plaster of Paris, quartz or marble dust, it acts as an arc quenching & cooling medium.

Under normal conditions, fuse element carries normal current without overheating. But when fault occurs, the current increases & fuse element melts before the fault current reaches its peak value.

- HRC fuse with tripping device – This HRC fuse is provided with a tripping device. When fuse blows out under fault conditions, the tripping device causes the circuit breaker to operate.

(Note: Low voltage HRC fuses may be built with breaking capacity of 16kA to 30kA at 440 V.)

-

High Voltage Fuses –

These are of three types – i) Cartridge type, ii) Liquid type & iii) Metal clad fuses

- Cartridge type fuse – This is similar to low voltage cartridge fuse type except that special design features are incorporated.These fuses are used upto 33 KV.

- Liquid type – These fuses are filled with carbon tetrachloride & have the widest range of application to HV system.

- Metal clad type – Metal clad oil immersed fuses have been developed with the object of providing a substitute for the oil circuit breaker.

Difference between a Fuse & Circuit Breaker –

| S. No | FUSE | CIRCUIT BREAKER |

| 1 | It is used for both detection & interruption of circuits, | It is used for interruption of circuits only, detection is done by a separate device called relay, |

| 2 | Its completely automatic | Requires additional equipment for automation. |

| 3 | Breaking capacity is small | Breaking capacity is very large |

| 4 | Operating time is very small 0.002 sec, | Comparatively large 0.1 to 0.2 sec |

| 5 | Requires replacement after every operation, | No replacement required |

Frequently Asked Questions (FAQs) on Electrical Fuse –

Q1) Where is Electrical fuse connected / installed?

Ans) Electrical fuse is always installed in phase wire to provide protection against over current. Fuse comes in different current (A) ratings for protection of different capacity electrical load/appliances.

Q2) Electrical fuse works on the principle of ? Working principle of electrical fuse?

Ans) Electrical fuse is inserted in the circuit & it melts when current exceeds the rated current of the fuse. For example, suppose a 10 A fuse is installed in a circuit, it means that circuit can easily carry current up to 10A. But, when current will increase further due to over current fault, the fuse will start heating up due to I2R losses where value of R (resistance) is fixed & current is increasing which will start heating up fuse & fuse will melt after some time. The time/duration of melting of fuse wire depends on the value of current. Fuse will blow off immediately on short circuit type condition where current value goes high multiple times than rated current of the circuit. While on over loading, fuse will take time to melt. Once fuse is blown, circuit continuity will be interrupted & load will be disconnected from the circuit.

Q3) How will you repair an electrical fuse?

Ans) Electrical fuse can’t be repaired because fuse wire is placed in a special heat resisting cartridge in which arc quenching/cooling media is filled. Therefore, once it is blown, we can open the cartridge & replace wire, hence, will have to replace it. Complete detail of construction of fuse is given in above sections of this page.

Q4) Why is an electrical fuse required in electrical system?

Ans) Electrical fuse is required in an electrical circuit to protect electrical appliances from over loading / short circuit.

Q5) How does use of a fuse wire protect electrical appliances? Or Explain how fuse protects the electrial appliances? Or how does the safety fuse ensure safety of electrical devices?

Ans) Answer of this question is given in Q2.